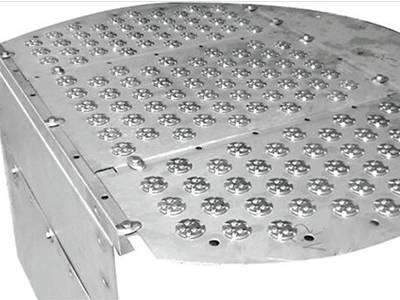

Floating Valves Tray Controls Vapor Flow Efficiently

Floating valves tray is a kind of tower tray which has many holes on the surface and there is a valve on each hole. When there is no upward gas phase, floating valves are closed on the tray. Floating valves, when gas phrase rises, will be opened by the impact of gas and their opening size will increase with the increase of the gas phase. Upward gas phrase, going through valve holes and being retained by floating valve plates, releases horizontally and laterally. Bubbling up from liquid layer, gas and liquid phases can fully make contact with each other to achieve an ideal heat and mass transfer effect. Due to their ability to control vapor flow, they provide a higher efficiency over a wider operating range than sieve trays.

FLVT-01: Floating valves tray can achieve an ideal heat and mass transfer effect.

FLVT-02: Top side valves on floating valves tray can be replaced easily.

FLVT-03: Floating valves tray can be customized to meet customers' requests.

| Model | The thickness of valves (δ) | The weight of valves (kg) | The thickness of tower tray (S) | Size | Material | ||||

|---|---|---|---|---|---|---|---|---|---|

| H | L | a | b | c | |||||

| FLVTS-01 | 1.5 | 0.0246 | 4 | 125 | 165 | 9.7 | 5.4 | 34.8 | 0Cr13 |

| FLVTS-02 | 2 | 0.0327 | 10.2 | 5.3 | 34.6 | ||||

| FLVTS-03 | 1.5 | 0.0251 | 9.7 | 5.4 | 34.8 | 0Cr18Ni9 | |||

| FLVTS-04 | 2 | 0.0333 | 10.2 | 5.3 | 34.6 | ||||

| FLVTS-05 | 1.5 | 0.0253 | 9.7 | 5.4 | 34.8 | 0Cr17Ni12Mo2 | |||

| FLVTS-06 | 2 | 0.0335 | 10.2 | 5.3 | 34.6 | ||||

| FLVTS-07 | 1.5 | 0.0243 | 3 | 115 | 155 | 9.7 | 5.4 | 33.8 | 0Cr13 |

| FLVTS-08 | 1.5 | 0.0248 | 9.7 | 5.4 | 33.8 | 0Cr18Ni9 | |||

| FLVTS-09 | 2 | 0.0330 | 10.2 | 5.3 | 33.6 | ||||

| FLVTS-10 | 1.5 | 0.0250 | 9.7 | 5.4 | 33.8 | 0Cr17Ni12Mo2 | |||

| FLVTS-11 | 2 | 0.0332 | 10.2 | 5.3 | 33.6 | ||||

| FLVTS-12 | 1.5 | 0.0246 | 2 | 105 | 145 | 9.7 | 5.4 | 32.8 | 0Cr18Ni9 |

| FLVTS-13 | 2 | 0.0327 | 10.2 | 5.3 | 32.6 | ||||

| FLVTS-14 | 1.5 | 0.0247 | 9.7 | 5.4 | 32.8 | 0Cr17Ni12Mo2 | |||

| FLVTS-15 | 2 | 0.0329 | 10.2 | 5.3 | 32.6 | ||||

Features

- Valves oriented parallel to liquid flow direction.

- No liquid flow under valves.

- Minimized weeping due to lateral vapor release.

- Wide legs and lack of valve rotation reduce damage and wear.

- Top side valve can be replaced easily.

- Durable valve tray with long service life.

Application

Floating valve trays are used in applications where higher turndown ratios are required. They are also widely used in distillation, extraction, medical, petroleum, chemical, oil refining equipment and many other fields.